Air Leak Inspection Business | Learn how we can identify air leaks even in difficult-to-find locations in manufacturing plants!

Kyowakiko’s air leak inspection business uses the special detector called the “Fluke high-performance ultrasonic sensor.”

There is a lot of reflected sound in the plants, so it is necessary to determine whether there is an air leak, but our experienced specialists can make that determination.

Please take a look at the video below, which shows an air leak inspection business, provided at a building materials and food equipment manufacturing plants.

We hope you can surely understand that testing can be easily done even in places that are difficult to get close to, such as high places or places where fire is used.

At the actual site, many other air leaks were found in addition to the two shown in the video.

In this article, we will explain the on-site air leak test results as shown in the video in seven parts based on the actual inspection reports.

This article will help you understand the features and benefits of Fluke’s high-performance ultrasonic sensors, so be sure to read it.

目次

- 1 Small air leaks that are hard to hear

- 2 Air leaks from air piping noisy, and at high altitudes

- 3 Air leaks in the dark

- 4 Air leaks from the inside of machine tools

- 5 Air leaks in areas where fire is used, such as industrial furnaces

- 6 Identify air leaks near your hands

- 7 Comprehensively identify air leaks throughout the plants

- 8 Summary

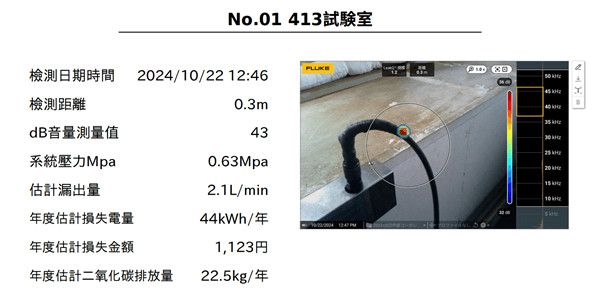

Small air leaks that are hard to hear

Air leaks occurred even in quiet places such as test rooms without any production machinery.

It is considered that at this site, the air hose sagged, causing stress to be concentrated at the bent part of the hose, causing it to break and resulting in an air leak.

The leakage rate was 2.1L/min, which was so small that it was difficult to hear, but the annual loss amounted to 1,123 yen.

It is common for the bent parts of such air hoses to crack due to aging.

It is important to install the hose without stress, and to periodically maintain any areas where bends may occur.

<413laboratory>

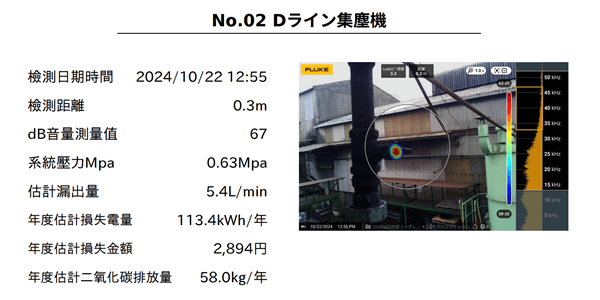

Air leaks from air piping noisy, and at high altitudes

Ultrasonic leak detectors can detect air leaks even in noisy areas or at high altitudes.

At this site, an air leak was detected from a joint approximately 5m above ground near the operating dust collector.

The leak rate was 5.4L/min (a strong hissing sound), and a leak, that would not be noticeable inside the plant in operation, was detected.

<Line dust collector>

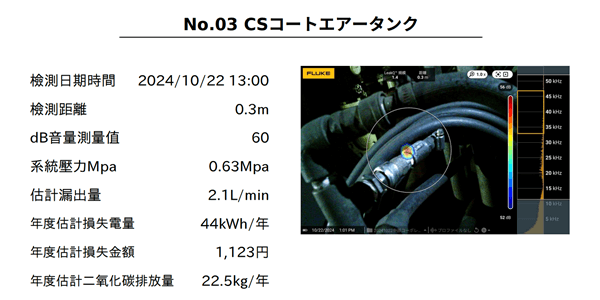

Air leaks in the dark

Air leaks may occur even in places where no one stay and the lights are not turned on.

Couplers also often become a cause of leaks due to aging, so care must be taken.

The leakage rate is 2.1 L/min, and the sound is very faint, making it extremely difficult to detect with anything other than an ultrasonic leak detector.

<CS coated air tank>

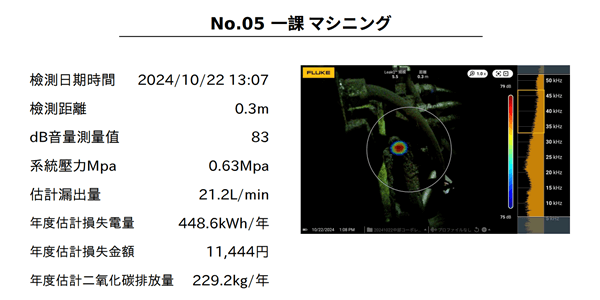

Air leaks from the inside of machine tools

In manufacturing plants, there are many machine tools to which the air is supplied.

It is common for an air hose to be connected directly to the machine tool, but in some cases the connection part may be housed inside the machine.

At this site, we were able to find a large air leak sound coming from inside the machining center, but because the connection was inside the machine, the exact location of the leak could not be identified.

The cabinet was then opened for inspection and a large leak was identified, with a leakage rate of 21.2 L/min and an annual loss of 11,444 yen.

<Machining Section 1>

Air leaks in areas where fire is used, such as industrial furnaces

The used ultrasonic leak detector has a maximum detection range of approximately 100m. Therefore, air leak inspections can be safely performed from a long distance in areas where fire is used, such as industrial furnaces, even in places other than high places.

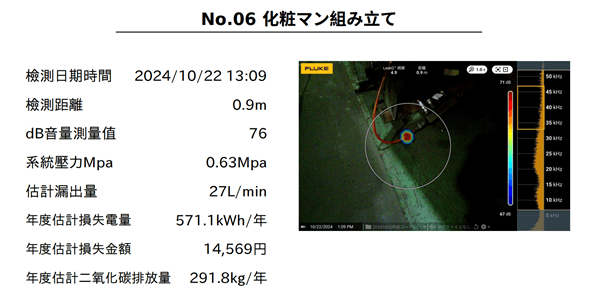

Identify air leaks near your hands

Of course, it can detect leaks other than those that are difficult to find, such as those we have introduced.

Even people who normally work nearby often find it difficult to notice the sound of air leaks if it becomes a part of their daily routine.

At this site, roughly half of the air leaks were coming from areas close to normal work areas, such as air tools, couplers at feet, and pinholes in hoses.

Among them was a pinhole with a large air leak, with an air leak rate of 27.0 L/min and an annual loss of 14,569 yen.

Why not take another look at the areas at your work site that are likely to be the cause of air leaks?

<Cosmetic machine assembly>

Comprehensively identify air leaks throughout the plants

The last benefit of using an ultrasonic leak detector is that it can comprehensively identify air leaks throughout the entire plant.

Conventional testing methods, such as checking by ear or hand or using soapy water, take a lot of time and effort, but this testing method allows for an accurate investigation in a short amount of time.

The time required for quantitative evaluation of one air leak is less than five minutes, making it possible to handle even large plants

Summary

We explained how air leaks can be identified even in areas of the manufacturing plant where it is difficult to find air leaks.

In principle, inspections can be carried out without any restrictions, even at facilities in operation and areas involving high-altitude pipes or fire.

At the manufacturing plant introduced this time, a total of 21 air leaks were discovered after a one-hour investigation, with the total air leakage amounting to 215.9 L/min and the total annual loss amounting to 116,465 yen, making it possible to quantitatively assess this extremely large loss.

Please rely on our air leak inspection business to investigate leaks that the human ear may miss, as well as locations that are difficult to inspect such as noisy locations, high places, dark places, inside machine tools, and locations near dangerous work such as industrial furnaces.

>>Air leak inspection business using a “sound-detecting camera

Thank you for reading to the end.

If the video article is well received, we will also publish videos of inspection scenes shown at other sites.

If you have any opinions or requests, such as “I would like to see a video of an air leak inspection on-site like this” or “I would like you to write an article like this”, please feel free to contact us through the inquiry form or the video comment section of the Kyowa Kiko official YouTube channel “Kyowa Kiko Channel“. We look forward to hearing from you!